Anaerobic Digesters & Bio Digesters Tanks: Lining, Repair & Restoration

Demand for biomass energy generation is growing steadily and future growth is expected to continue.

The Client

The demand for biomass energy generation is growing steadily and future growth is expected to continue.

Corrosive activity within the chambers

Highly corrosive environments

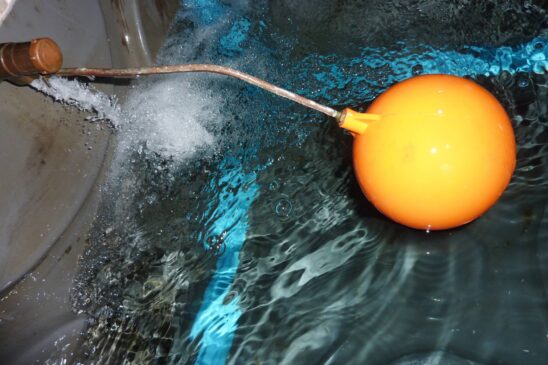

Many elements of a biomass plant can be and will affected by corrosion. The fermentation and oxidation processes used by a biogas plant’s anaerobic digesters, whether concrete, steel or stainless steel, create a perfect environment for corrosion, both at the gas and liquid phases.

It is the presence of moisture reacting with contaminants, such as hydrogen sulphide (H2S) that generates highly corrosive sulphuric acid.

Internally, steel digesters are typically protected by a glass or a high performance technical lining system. Sludge tanks also face similar corrosion issues and maintenance issues. Typically it is in the vapor space at the top of the tank on the walls and the underside of the roof which will suffer the most severe corrosion activity occurring. In addition to this the internal pipework will as be attacked by corrosion.

Steel & Stainless Steel Digesters

Glass-lined steel digesters and tanks provide excellent corrosion resistance to acids, alkalis, water and other chemical solutions (with the exception of certain acids such as hydrofluoric acid and hot concentrated phosphoric acid). As a result of this chemical resistance, glass lining can serve for many years in environments that would quickly render most metal vessels generally unserviceable by many companies, other than ourselves.

Mechanical damage to the glass lining during the life of the digester, or even accidental damage during the installation stage of the tank, can result in small holes in the glass lining. Aggressive chemicals produced during the anaerobic digestion process have access to the steel and corrosion can set in during both the liquid and gas phases.

We see tanks with pinholes in the glass lining ranging in size from 2mm to 5mm in diameter, which when left unchecked the corrosive activity can fairly quickly eat through the tank wall, leading to the escape of liquid digestate or methane.

We have often seen digesters and also glass-lined tanks on farms where the external damage in areas perhaps 200- 300mm of chemical attack to the steel, and yet inside the tank, the original pinhole or damage mark was only 2-3mm in diameter.

Over the years we have been involved with the application high performance chemical resistant resin and polyurea-based lining systems for the lining of steel and stainless steel digester tanks.

Stainless Steel Digesters

We often see stainless steel digesters with the top ring or top couple of rings suffering from corrosion which has resulted into to formation pinholes through the steel and the tank becoming unusable.