Green King Brewery: Stainless Steel Liquor Tank Lining

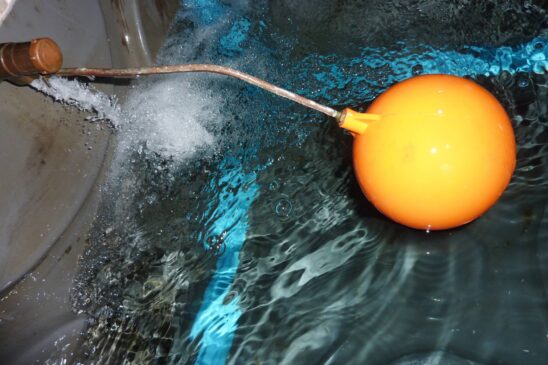

A well-known brewery located in East Anglia required additional cold liquor (water) storage capacity for a relatively short time.

The Client

The brewery decided to use an old stainless steel fermentation vessel that was conveniently located in a relatively disused section of the brewery. We were commissioned to update the tank, however, there was a problem in that it had a number of small undetectable leaks.

Challenges

- The vessel was completely insulated and inaccessible from behind.

- A number of leaks had to be identified and repaired.

- The lining material used had to be food contact grade or potable water grade.

Solution

The surface of the tank was grit blasted with a hard carborundum-based grit blasting abrasive to provide a strong mechanical key on the stainless steel surface. After a thorough cleaning, we applied a new potable water tank lining system.

The material used was a solvent-free, two-pack, low odour epoxy resin-based system that is both food contact and potable water approved.

Due to the small size of the tank, the new lining was applied by hand. Following the application of the new lining and an overnight curing period, we checked the tank lining for the absence of microporosity and dry film coating thickness.

The Results

The newly applied potable water lining stopped the leakage and gave the brewery their much-needed additional storage capacity utilising previously redundant existing equipment and with minimal financial outlay.