Narrowboat Water Tank Lining

The owner of this delightful narrowboat contacted us for technical advice and for the supply of materials for the lining of a corroded – rusty steel drinking water tank on her narrowboat.

The Client

We were contacted by the owner of this narrowboat as they wanted a solution that would last, cleaning out water tanks is rarely a pleasent task, it’s condition and location on the boat, made it perfect for our system.

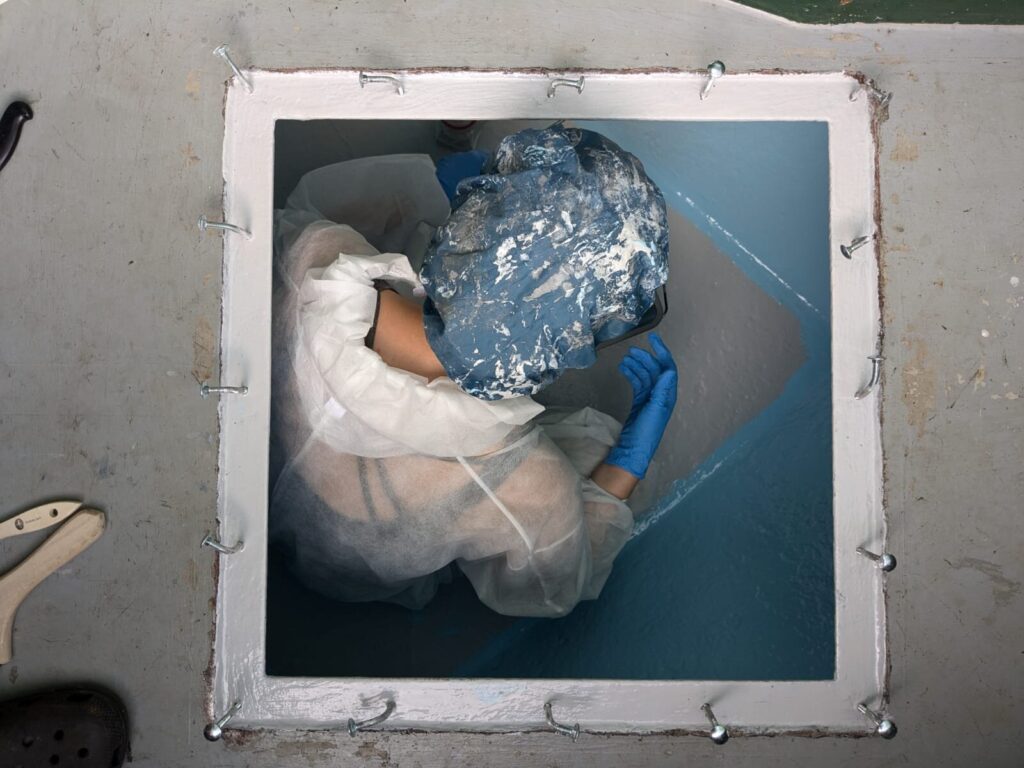

Ideally, our client wanted to be able to carry out the work herself.

“I was really happy with the product and the outcome. The paint went on easily and the different coloured coats meant I could work systematically and be sure I had even coverage. Especially helpful when working with the 15 minute pot life!

Being new to both boating and DIY, this project was a big job for me, but the team answered all of my many questions over email and were even on the phone to me when I needed help mid-job.

It’s so great to have a working water tank again!”

Thank Shona, glad we could help.

Challenges

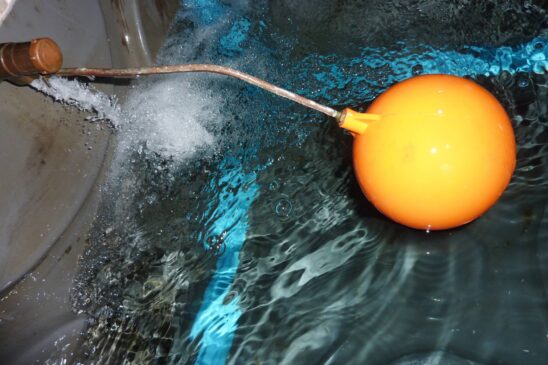

- The narrowboat had an integrated water tank was built into the structure of the narrowboat which could not be removed.

- The narrowboat was likely to remain in the water whilst the work was carried out so the surface of the steel would be both cold and potentially damp.

- There was limited space to work in.

- The owner of the narrowboat wanted to carry out the work herself.

Solution

This is a system that we have provided to many narrowboat owners in the past.

Our specification for this project was the supply of materials that included an anti-corrosion surface and damp tolerant resin primer coat and a damp surface tolerant drinking water approved intermediate and top coats.

The materials were both based on epoxy resin technology and had the advantages of being:

- Solvent-free.

- Low odour & pleasant materials to work with.

- It does require some practical and technical ability to do this and it does need to be carried out by a competent person. However with the aid of our detailed instructions/ guide notes, which are based on our own extensive experience and years of training people, many people are successfully doing this now and we do provide an excellent free technical support via a phone call or, for a small fee to cover our expenses and time, a site visit if required.

- Compatible for use on tanks that have had a previous bitumen lining and being solvent free and low odour, will not allow the bitumen to bleed through and contaminate and/or taint the water.

- High anti-corrosion and impermeability properties.

- Glass flake reinforced technology top coat to create an impenetrable surface.

- Drinking water approved.

- Finished in a light colour.

- Designed for use in confined spaces.

- Long-lasting and durable.

Support

We provided detailed technical advice regarding surface preparation, mixing and application of the materials and also help pages for getting around troubleshooting problems and if required the tools and equipment to carry out the work too.

Unlike other companies, we are happy to give telephone support, even out of hours and at weekends, to help with general guidance, technical questions or simply moral support. We would rather talk you through something, even if it is confirming that everything is ok, rather than you worrying about something that could be easily fixed with a quick phone call.

With correct surface preparation, this system will give narrowboat owners many years of maintenance-free use.

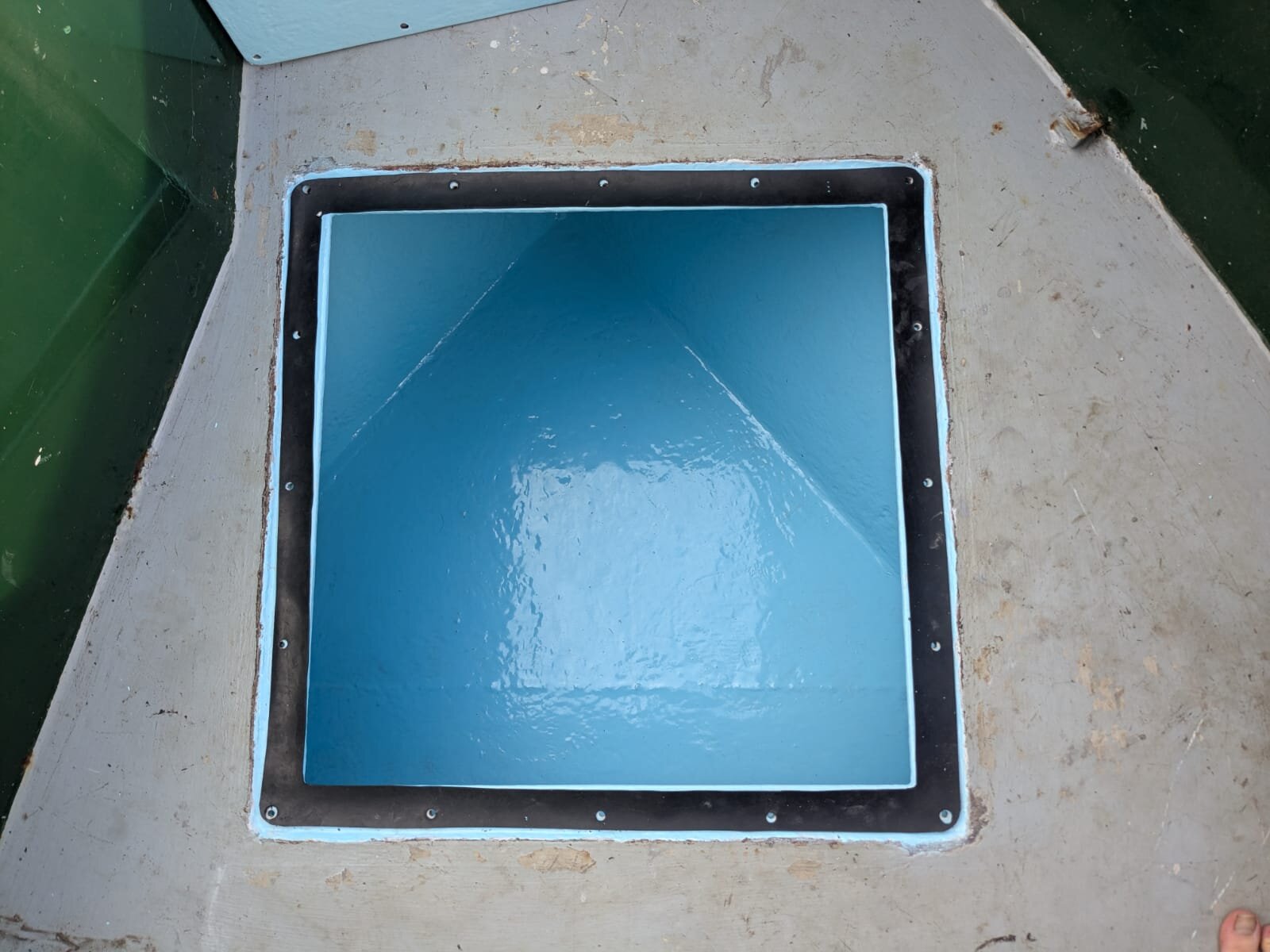

Narrowboat Water Tank Lining Before and After Treatment

The Results

Our solution will provide the owners with many years of maintenance-free sweet tasting water from the water tank on this narrowboat.