Retford Leisure Centre: Underwater Coating Application

We were instructed by Balfour Beatty to coat two drainage sumps to mitigate the risk of seepage or leakages in one of the swimming pools at Retford Leisure Centre.

The Client

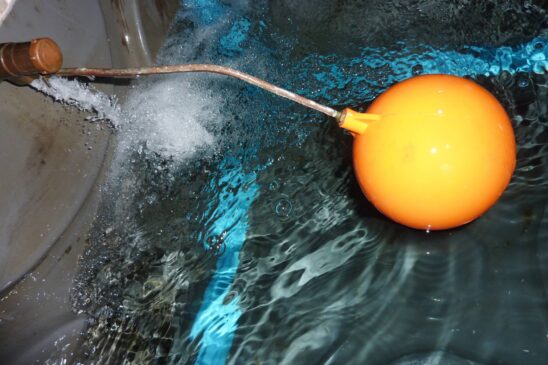

Due to time and cost restraints, the swimming pool could not be drained.

Challenges

- The swimming pool could not be drained due to time and cost restraints.

- The work had to be carried out underwater.

- Diving equipment was required to complete the project

Solution

We recommended a liquid resin epoxy coating system for this project, which could be applied and would fully harden underwater. This removed any need to drain the pool and any potential downtime normally associated with such an operation.

We brought all the equipment, including scuba diving kits, means of abrading surfaces and specialised underwater epoxy coating materials. Our team removed the sump grilles to carry out detailed inspections of both sumps, which along with various pipework were constructed from concrete, fibreglass and stainless steel. All accessible areas within the confines of the sumps were abraded to produce a mechanical key, ready for the new coating to be applied. The prepared surfaces received the underwater epoxy resin coating system in two forms. Firstly, a high viscosity resin paste filled any gaps, craters, voids or cavities within the sumps. We then applied a second, lower viscosity coating to all the internal surfaces of the sumps.

After Surface Preparation

The Results

Our highly specialised material was applied with care and the resin adhered well to the surfaces without floating off or contaminating the pool. To minimise disruption to the leisure centre, we worked out of hours. The project was completed just before midnight and, due to the warmth of the water, it was possible for the pool to return to full use when the leisure centre opened to the public the following morning.