School Sports Centre: Galvanised Steel Cold Water Storage Tank Coating

Having carried out various successful tank lining and refurbishing projects for a London school

The Client

We were re-commissioned to reline three galvanised steel cold water storage tanks located above the school sports centre.

Challenges

- All three tanks revealed deep craters in the steel, which left untreated would have caused leaks.

- The building was in constant use so work had to be carried out swiftly within the half-term break.

- The tanks were located within a small void in the roof and accessed via a small doorway hatch.

- Some tanks were coated with the original black bitumen, which was failing.

- Replacing three tanks would have required the removal of the roof and crane hire; a costly, time-consuming and disruptive alternative.

- Due to the location of the tanks, non-disruptive surface preparation was required.

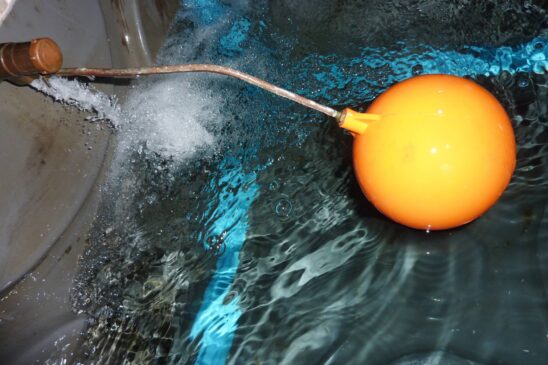

Before tank lining treatment and craters in the tank floor

Solution

To avoid the unnecessary and expensive replacement of three water storage tanks, we recommended the use of our potable water tank lining system. Our in-situ water tank lining system was specifically developed for the refurbishment or repair of tanks located in difficult-to-reach areas, such as attic voids and roof spaces using manual surface preparation methods.

By using this innovative solution, each tank could be quickly and conveniently reconditioned to the required standard with minimum disruption to the school’s activities. Following extensive surface preparation and cleaning, we applied an anti-corrosion primer. We repaired the floors of the tanks with our reinforced resin-based screed system, which in effect built new floors within the tanks. This was followed by four coats of the water-grade tank lining resin system. Finally, the tanks were checked for the absence of micro-porosity in the new lining and overall coating thickness.

After water tank lining treatment

The Results

Our water tank lining system again proved to be less intrusive and more cost-effective than replacing the tanks. Even with the additional work of applying the floor screed to each tank, the project was successfully completed on time and within budget. This refurbishment project will extend the practical working life of each tank for a further fifteen to twenty years.