Tank Lining Stainless Steel Digester Lining with Polyurea

The top ring of the bolted stainless steel digester tank had corroded as a result of the incorrect type of stainless steel being used for an aggressive digester environment.

The Client

The top ring of the bolted stainless steel digester tank had corroded as a result of the incorrect type of stainless steel being used for an aggressive digester environment.

Our Solution

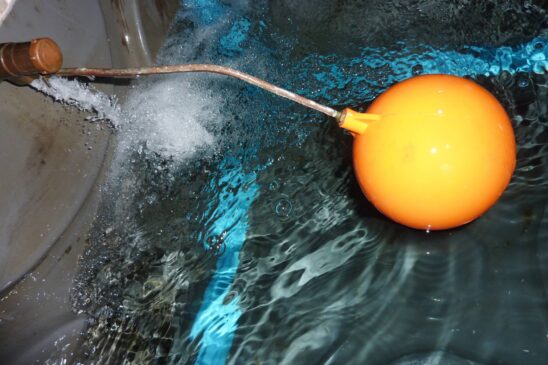

Following the replacement of the badly perforated sheets, we proposed the application

Initially, all surfaces were prepared by the method of abrasive blasting – essential when applying tank linings to stainless steel as it is an extremely difficult surface to adhere to. A minimum surface profile of 75 microns was achieved and tested using a surface profile needle gauge.

Following blasting, all surfaces were washed using a high-pressure spinning jet and incorporating a degreasing agent to ensure that all surfaces were spotlessly clean and free from contaminants.

SPI Corrolastic HT was then applied to a thickness of 2mm, incorporating SPI’s AE4 adhesion promoter – which enables the material to bond tenaciously to difficult surfaces such as stainless steel.

SPI Corrolastic Pure Polyurea is the perfect tank lining material for this application as it has the flexibility and elongation properties to cope with the lateral movement and deflection that can be present in bolted tanks such as this one. This is in conjunction with good chemical resistance.

As part of the standard quality assurance, the polyurea tank lining was checked for porosity using a DC holiday spark tester and repairs were made where necessary.

Finally, termination points were sealed using a polyurethane jointing compound. These works were warranted for 10 years from completion, with a life expectancy in excess of 25 years.