Fibreglass Tanks

(including leaking joints and cracks fibreglass tanks)

Fibreglass tanks have started to leak water either through a crack or cracks that have recently developed in the tanks or leaks in bolted sectional panel tanks where the panels connect.

Leaks in sectional panel tanks are usually due to the age of the tank and the jointing compound starting to fail. There are other reasons as well, but the failure of the jointing compound is the most common cause.

Previously this would have meant the partial or complete dismantling of the tank sections, new jointing compound and the tank reassembled.

Rather than replacing existing fibreglass water tanks, more often than not they can be repaired and if required, have a smooth impervious internal finish lining applied. This will both save considerable costs and will also extend the practical working life of the tank, avoiding the downtime and inconvenience of replacing the tank.

Reasons for considering replacing an existing fibreglass water tank may include:

- Leaking from between the panel joints

- Seeping water from a crack, unable to locate where from

- The tank is old with rough & uneven surfaces

- Osmosis

- Increased capacity required

- Time restraints

Apart from one item, our special tank repair treatment system can handle all of the rest.

A common problem with existing fibreglass tanks is that some start seeping or leak water either through a crack that has recently developed in the tank or seepage from the joints in bolted sectional panel tanks where the panel sections connect.

Fibreglass water tanks that have been made in a mold as a single structure, are that with age, along one or both sides of the tank a crack will form where the wall of the tank moves or flexes as the tank is filled and emptied.

Leaks in sectional panel tanks are usually due to the age of the tank and the jointing compound starting to fail. There are other reasons as well, but the failure of the jointing compound is the most common cause.

Previously this would have meant the partial or complete dismantling of the tank sections, new jointing compound and the tank reassembled.

This usually has serious cost implications and downtime for the owner of the tank and inconvenience to anyone, tenants, etc, who rely on the supply of water from the tank.

In-situ localised repairs, minimal disruption, quick return to service.

Rather than go to the expense of replacing that tank this can be repaired.

The same applies to the treatment of osmosis when found in a fibreglass tank.

The repair is usually completed in a single day and after testing then the tank is returned to service later that same day.

Our tank lining system is suitable for both potable and non-potable water storage use.

It provides long-term protection and extends the working life of the tank. The smooth impervious surface finish of our tank lining system will make it easier to keep the tank clean and inhibits contamination and the growth of bacteria, including Legionella and micro aquatic organisms.

Water tank resin lining systems are suitable for:

- Galvanised Steel Tanks

- Leaking Water Tanks / Rusty Bolts, Support Braces, and Fixings

- Sectional Panel Tanks

- Braithwaite Water Tanks

- Osmosis, fibreglass tanks with

- Glass Reinforced Plastic (GRP) – Fibreglass Water Tanks

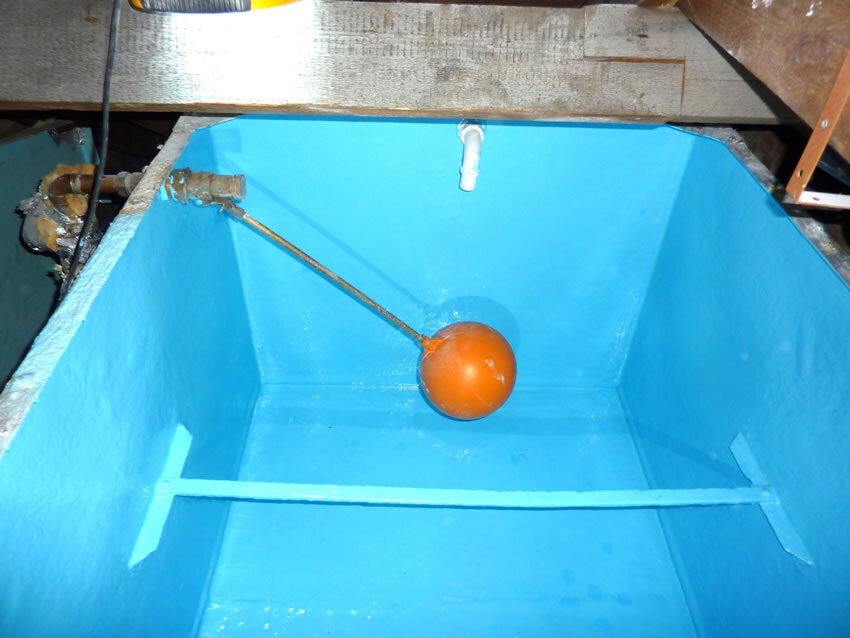

- Tanks in difficult-to-reach areas e.g. attics

- Potable cold water storage tanks

- Potable fresh hot water tanks

- Bitumen – tanks with pre-existing bitumen lining

Our water tank lining system provides:

- Solvent-free tank lining system

- Prolongs the life of existing tanks

- Easy clean, smooth finish

- Repairs to cracked and leaking tanks

- Capital savings

- Potable water approved

- Minimal disruption

- Low odor and taint free

- Quick completion

- Long-term protection

- Avoids costly repairs

- Solution for osmosis

- Minimal disruption

- Reduction in the potential risk of Legionella and other micro aquatic organisms

- Ideal for tanks in difficult-to-reach areas

- A cost-effective repair solution for leaking and corroded water tanks

- Compatible with existing bitumen-based tank paints

Joint Repairs – Leaking Bolted Sectional Panel Water Tanks

We often have called asking if there is anything that could be done to treat the joints of bolted sectional fibreglass tanks that have started to have water seeping or leaking from the panel joints – invariably the problem is with the jointing compounds becoming old and no longer effective and not with the actual panels themselves.

In response to this, we developed a repair system and method specifically to address this problem.

The system we developed has proved, as intended, to be repeatedly reliable and the method allows for the tanks to be repaired and water leaks stopped by treating the joints only and avoiding the unnecessary expense of applying a new lining to the entire tank or having to dismantle the tank to replace the original jointing material.

We now have an ever-extending successful track record of many tanks being treated with this method which saves on downtime and avoids additional unnecessary expense.

We can do this for you or supply you with the materials and technical support to enable you to carry this out yourselves.

It does require some practical and technical ability to do this and it does need to be carried out by a competent person. However with the aid of our detailed instructions/ guide notes, which are based on our own extensive experience and years of training people, many people are successfully doing this now and we do provide excellent free technical support via a phone call or, for a small fee to cover our expenses and time, a site visit if required.

Fibreglass tanks that have started seep or leak water either through a crack or cracks that have recently developed in the tanks or leaks in bolted sectional panel tanks where the panels connect.

Leaks in sectional panel tanks are usually due to the age of the tank and the jointing compound starting to fail. There are other reasons as well, but the failure of the jointing compound is the most common cause.

In this Section

- 1Tank Linings

- 2Bund Lining

- 3Water Tank Lining & Tank Joint Repairs

- 4Fiberglass Tanks

- 5Brewery, Winery, Distillery and Food Industry Tanks

- 6Conrete Tanks & Chambers

- 7Hot Water Tanks

- 8Heat & Power

- 9Commercial & Industrial Tank Lining

- 10Marine & Maritime

- 11Narrowboats, Barges, Wide-beams, Canal Boats, Houseboats, Leisure Cruisers & General Water Craft

- 12Steel Tanks

- 13Food & Drink