Heat & Power

Gas and Oil companies are under constant scrutiny regarding EHS, our lining system will provide maximum sustainability.

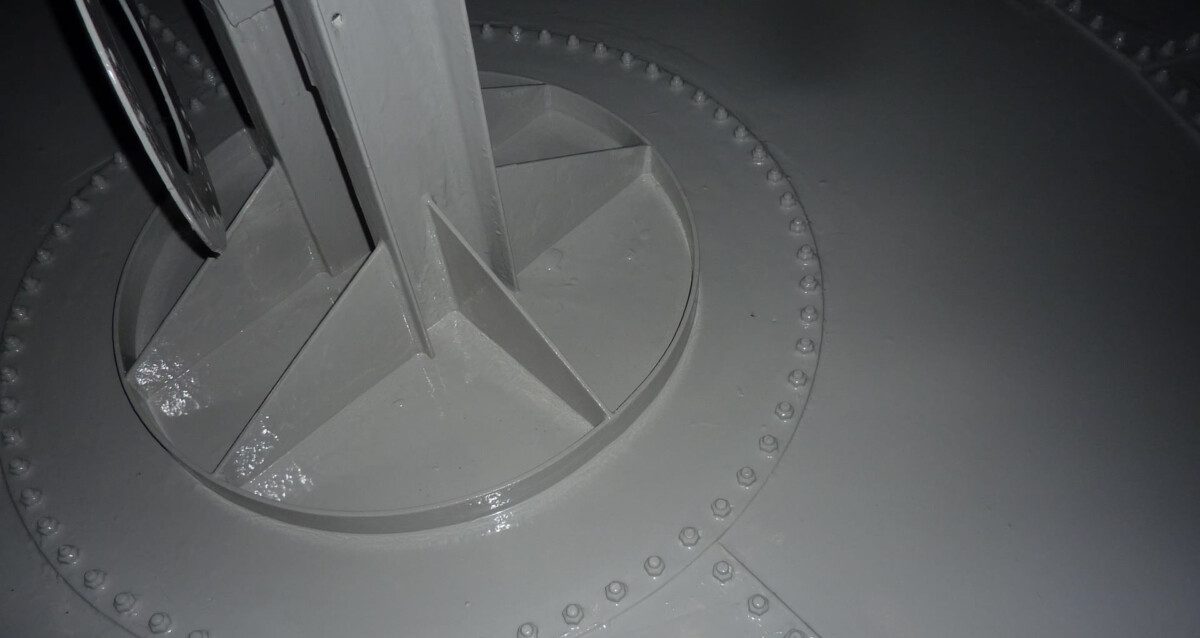

We have lining systems which withstand an aggressive environment within the heat and power industry with endurance to temperatures up to 500oC and is resistant to corrosion and thermal shock. Ideal for large tanks we supply our own safety equipment and our technicians are highly trained in health and safety within this sector.

We carry out full quality control measures through every aspect of the tank lining works. Once our work is completed we test electronically the new lining system for general thickness and absence of micro-porosity. Bring existing tanks back into optimal use and extend tank expectancy by many years.

- Steam condensate return tanks.

- Hot water calorifier tanks.

- Can be 10% of the cost of replacing tanks.

- Extends tank life expectancy by potential 15 + years.

- VOC – free.

- BPA – free.

- Solvent-free.

- Non-toxic.

- A cost-effective alternative to tank replacement.

In this Section

- 1Tank Linings

- 2Bund Lining

- 3Water Tank Lining & Tank Joint Repairs

- 4Fiberglass Tanks

- 5Brewery, Winery, Distillery and Food Industry Tanks

- 6Conrete Tanks & Chambers

- 7Hot Water Tanks

- 8Heat & Power

- 9Commercial & Industrial Tank Lining

- 10Marine & Maritime

- 11Narrowboats, Barges, Wide-beams, Canal Boats, Houseboats, Leisure Cruisers & General Water Craft

- 12Steel Tanks

- 13Food & Drink