Materials & Product Sales

(including resin repair kits & application equipment)

As experts in the installation of advanced tank lining and flooring systems, we are able to supply a range of innovative resin materials directly to commercial contractors and domestic end-users.

Our range of high-performance resin materials is ideal for the maintenance of water and other tanks as well as air conditioning units found in factories, breweries, chemical plants, engineering departments, hotels, apartment blocks and domestic properties.

Our resin systems, with suitable surface preparation, can be bonded to a wide range of materials, including concrete, steel, fibreglass, timber, and many other substrates. We also have specialist grades that are fuel resistant, resilient to high temperatures and others that can be applied under water or within tidal zones.

Our tank lining resin materials are suitable for a wide variety of uses, including:

- Food and beverage production and storage applications

- Potable water storage applications (cold water storage)

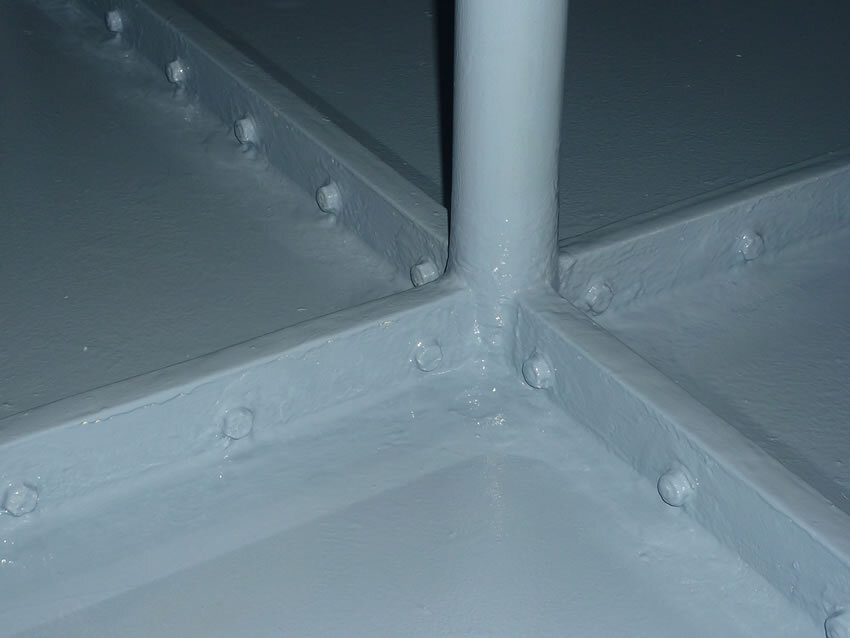

- Repair of leaking tank joints (bolted sectional tanks)

- Air conditioning units

- Wastewater applications

- Engineering repair departments

- Diesel & petrol fuel storage tank applications

- Suitable for moisture and wet surface tolerant applications

- Offers superb resistance to osmosis and water ingress

- General marine and narrowboat maintenance and repairs

- Concrete tank linings and concrete repairs

- Damp, wet, or green concrete

- Bitumen – tanks with pre-existing bitumen paint

- Wastewater treatment processes

- Waterproofing and repairing of various surfaces and materials, including fibreglass, concrete, and wood

It is worth noting that these materials are completely compatible for use on tanks that have had a previous bitumen lining and will not allow the bitumen to bleed through and contaminate and/or taint the water.

Applying the materials

Is this something that I can apply myself, or do I need to get you in to do this for us?

It does require some practical and technical ability to do this and it does need to be carried out by a competent person. However with the aid of our detailed instructions/ guide notes, which are based on our own extensive experience and years of training people, many people are successfully doing this now and we do provide excellent free technical support via a phone call or, for a small fee to cover our expenses and time, a site visit if required.

Repair Kits

We supply a range of resin materials in small handy repair kits, which are ideal for lining or repairing small tanks and also for making localised repairs to existing linings. The repair kits are also a really efficient general purpose repair material. The resin used in these kits are usually two-pack epoxy resins and with suitable surface preparation, will bond to steel, (galvanised & carbon), fibreglass, concrete, wood, and many other substrate materials.

Resin repair kits are usually supplied in 0.5 kg units of pre-weighed parts A & B.

Other quantities or sizes can be made for specific applications for convenience or of use (50g, 100g, 250g – 1kg) or as required.

Add together the premeasured two-component epoxy resin (parts A and B), mix thoroughly, and apply it to a suitably prepared surface.

For larger tanks or projects, we can supply the materials in 5kg bulk units.

It is important to follow the instruction or guide notes given, if in any doubt at all, contact us.

For convenience, we also offer a supply of surface preparation equipment and resin application equipment, the same as we use ourselves.

These include microfibre rollers, natural bristle application brushes, tool cleaning solvent, thickening agents, fibreglass reinforcement bandages, resin application scuttles and more.

Because almost every tank is different, it is better to contact us directly so that we can advise on the most suitable tank lining material system for your project and what quantities you would require.

Generally, we would need to know the following:

- What the tank is being used for

- What the tank is made from

- Dimensions or capacity of the tank

We include fully detailed guide note instructions which include details for surface preparation and application of the materials when sending out the materials purchased.

With correct surface preparation and application, the treated tank will extend the working life of any existing tank by many years.

If you have access to abrasive grit blasting, then the applied lining or coating system will last even longer.

The processes involved are relatively straightforward:

- Empty and dry the tank

- Brush off and remove and loose debris

- Scrape and then abrade all internal surfaces to remove any loose or weak material from previous paint or coatings and to produce a strong machinal key for the new tank lining

- Brush and vacuum the tank

- Apply primer coat, if required

- Apply intermediate coat

- Apply top coat

In recent years we have seen steady growth in the use of our resin systems in the leisure and boat sector, not only for the lining and repair of water and fuel tanks but also as a general repair material. Once applied, epoxy resins offer a combination of lightweight, durable, impermeable and robust properties.

Click on the link to see more

Areas of Use

The same lining system can be used as a highly efficient coating or repair material for the following areas:

- Fresh or potable water tanks

- Localised repairs to any leaking steel or fibreglass tanks

- Fuel Tanks (diesel, petrol, and kerosene/paraffin)

- Engine Room floor and walls (can also be made as an anti-slip coat with high abrasion resistance for high traffic/wear areas)

- Gas lockers

- Bunded containment area

- Black water tanks

- Bilge tanks/areas

- Gray water tanks

- Repair of leaking pipes

- External hull coating.

- Creating anti-slips areas

Exceptionally good as a wide-range repair material for almost any material including steel, timber or fibreglass

Available in a limited range of different colours available for diffident projects i.e., black for the hull external coating and lighter colours for inside tanks and engine rooms etc.

We can supply the materials to almost any RAL or BS colour required. Depending on the colour required, there may be, a minimum order quantity requirement of 50kg.

Frequent Questions and Answers:

1. Is your tank lining system suitable for cold water tanks?

a. Yes

2. Are your materials suitable for lining fuel tanks?

a. Yes

3. Does the tank have to be removed (from the boat or building) to carry out the lining process?

a. No. Our materials are designed to be used in confined spaces without special equipment.

4. Does the boat have to be lifted from the water to carry out the tank lining work?

a. No. Our materials are designed for use in damp conditions.

5. Is this something I can do myself or do I have to get a specialist in?

a. It does require some practical and technical ability to do this and it does need to be carried out by a competent person. However with the aid of our detailed instructions/ guide notes, which are based on our own extensive experience and years of training people, many people are successfully doing this now and we do provide excellent free technical support via a phone call or, for a small fee to cover our expenses and time, a site visit if required.

6. How long does it take to line a water tank?

a. Usually between 2 and 3 consecutive days

7. Smells: Are there strong smells when working with the resin tank lining materials?

a. No – All the materials that we supply and use are low odor and solvent free and designed for use in confined spaces. See instruction/guide notes for more details.

8. Our tank had once been painted with bitumen. Are your materials suitable for this and will the bitumen bleed through your material?

a. Yes the material is most definitely suitable and is recommended for the lining of tanks that have had a previous bitumen lining. It should be noted that bitumen is no longer approved or allowed for use as a lining for potable water tanks. Our materials are completely solvent free and will lock any remaining bitumen in place and stop any bitumen bleed through.

9. Food & Drink: Are the tank lining materials suitable for food and drink contact us?

a. Yes.

10. Aggressive chemical applications: Are the tank lining materials suitable for aggressive chemical environments such as lining black water tanks and bunded containment areas?

a. Yes. Contact us for details.

Equipment List

Here is a list of the basic application equipment that you would require for the lining of the tank. Some people do find it useful for us to supply these items because they are the same as we use ourselves. If this is of interest to you then please let us know what you would like, and we can include them in the quotation.

- Rust & Surface Chipping Hammer/s, with spring handle for wrist strain reduction.

- Rust Scrappers, with comfortable handles & 2″ tungsten carbide blades

- Replacement blades for rust scrappers

- Deep resin scuttles 5ltr 200mm 8″, rectangular

- Resin application Roller frames, short handle 10″ x 100mm (4″)

- Microfibre roller refill heads 100mm (4″) Packs x 10

- Telescopic extension Pole/s (reaching into the tank to coat final areas)

- Bucket trowels, resin mixing & scraping out drums

- Natural bristle brushes for resins 50mm (2″)

- Resin Mixing/Blending Paddle for resin, Gentle Action, Rotary, 4″, 100mm x 600mm. Used with slow-speed electric drills with a 10mm or larger chuck.

- Disposable Nitrile gloves, Box x 100

- Solvent Tool Cleaner x 1ltr bottle/s, Sc-Sol

- Hole filling Thickening Agent, Thixotrope S51, White, pot x 30g

- Multi-directional woven fibreglass (reinforcing) bandage 100mm wide x / linear metre.

Bulk Units

A range of epoxy resins is available in 5kg and 20kg bulk units. These materials are suitable for a wide variety of tank lining applications, including cold water tanks, chemical tanks, fuel tanks and beverage storage and process tanks.

Flooring Systems

Whatever your industry sector, we can provide a surfacing solution that incorporates a range of high-performance properties, including anti-slip and chemical resistance. Floor coating resins are available in almost any colour and quantity to suit your exact requirements. Bespoke or custom colours can be created at a small additional charge.

In this Section

Client Testimonials

“Hello Peter,

I’ve just finished the largest of the two tanks (Grey). I must say that it was a pleasure using your recommended products, the primer especially is impressive. After I had applied one tin of the top coat and then measured coverage per tin it was plain sailing as you had allowed just the right amount of product, I had two tins leftover which is by far better than two short. The client is very happy and also happy to have the two tins for future repairs, although I don’t think he’s going to need them. I’d most certainly be happy to recommend your product in the future, should the need arise.

Many Thanks

Paul”

“Peter,

Sincere thanks for going above and beyond. Understanding the business we are in is positive, being prepared to be more than another supplier is epic. I may make enquiries into local authority needs for your product moving forward.

Kind regards

Michael Walsh

Walsh & Son Ltd“

“Dear Peter,

We have completed the refurbishment of the mixing vessel and the painting of the inside went very well, the final effect was excellent in terms of finish and appearance. Since then we have had our quality assurance audit and the auditor was very impressed with it, he had not seen a vessel treated in this way before but thought it was very effective.

Best wishes

Peter Clough

Director – Bickiepegs Healthcare“